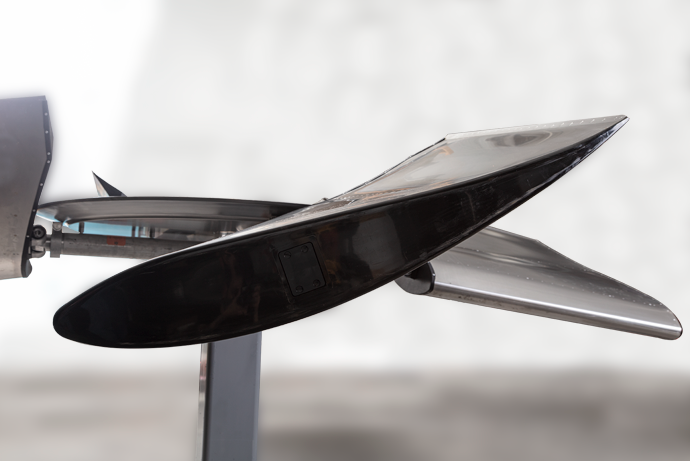

When noise levels must be kept to an absolute minimum, rely on the Class 10000 Minimum Acoustic Geometry (MAG) fan. Our MAG fan blades feature an exceptionally smooth surface, achieved through advanced robotic spot welds and flush rivets. The key to a quieter fan lies in the blade's design, a science that Moore Fans has perfected over decades.

With wider chord blades, the MAG fan can operate at lower speeds while delivering the same powerful airflow, significantly reducing noise. Our use of flush rivets further minimizes drag, resulting in performance and sound levels that rival the quietest axial fans available.

For hazardous or potentially explosive atmospheres, our plastic ATEX-certified tips ensure safe and spark-free operation while root seals prevent water and other contaminants from entering the body of the blade.

Engineered for engine-driven applications, the Class 10000 MAG fan accommodates diameters from 5 to 24 feet and supports both left-hand and right-hand orientations.

We custom manufacture all of our fans to suit your specific application. Our optional equipment and services help ensure our fans fit your exact requirements.

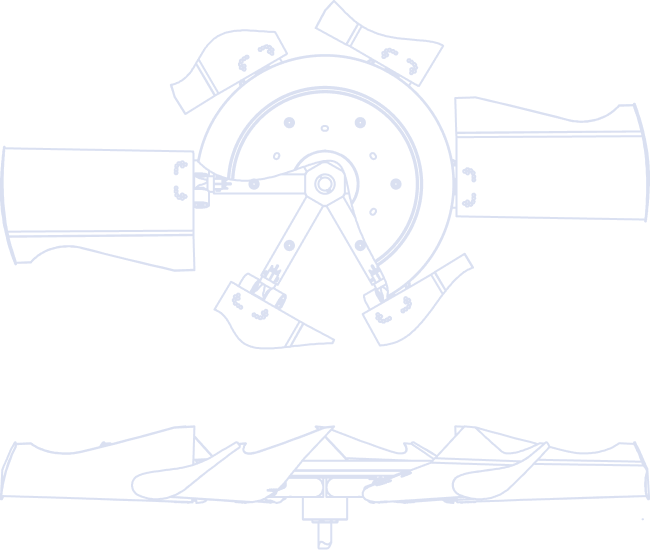

AirBrake®

Our anti-windmilling device easily installs on the shaft or bushing of your fan drive system to prevent reverse rotation. Maintenance-free and featuring a low-profile design, AirBrake® makes your fans safer to maintain while extending the life of your drive systems.

Extended Hubs

Extended hubs allow for greater clearance between the fan and drive system, which makes them ideal for installation directly on the motor or gearbox and in a wide range of aftermarket situations.

As your partner in air flow solutions, we’re always at your service. Whether you are facing a new air movement challenge or need service and support, our experts are here to collaborate with you. Our team is part of your team.

Contact Us